電話番号: +81 3-5288-7074

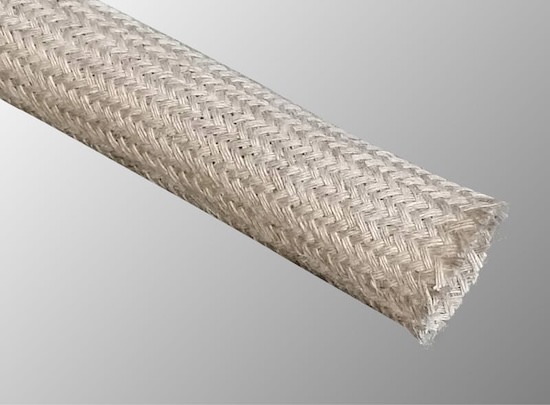

フラックススリーブ

フラックススリーブは梁や中が空洞の構造物など、様々な形状の成形に適しています。適切な加工方法を用いれば、スリーブの補強繊維が成形用の芯材の縁まで継ぎ目なく密着し、気泡のない仕上がりが可能です。さらに、使用する樹脂にも十分に浸透するため、強度を損なう心配がありません。ねじれやせん断に対する強度を高めたい場合は、繊維角度を45°にするのが最適とされています。フラックススリーブは、引き伸ばしたり縮めたりすることで直径を調整可能で、その場合の繊維角度は30°〜60°が理想的です。繊維の長手方向に補強が必要な場合は、一方向にUD糸を編み込むことで対応できます。

天然繊維であるフラックススリーブは100%リサイクル可能であり、ガラス繊維スリーブに匹敵する高い引張強度を持ちながら、より軽量で環境負荷の少ない素材です。

エポキシ樹脂やポリエステル樹脂に含浸させることで、天然繊維複合材料として加工することができます。

ご注意!

ご要望に応じて、直径0.1mmから500mmまでの各種サイズをご提供可能です。

こちらに掲載しているのは、サイズ例となります。

品番 直径/45° 厚さ 重量(kg)/100m 重量(kg)/m²

7102 10 1,00 0,99 0,42

7735 22 0,80 2,10 0,39

7693 38 0,67 1,23 0,14

6560 50 0,65 3,09 0,27

7052 105 0,80 8,16 0,32

| 品番 | 直径/45° | 厚さ | 重量(kg)/100m | 重量(kg)/m² |

|---|---|---|---|---|

| 7102 | 10 | 1,00 | 0,99 | 0,42 |

| 7735 | 22 | 0,80 | 2,10 | 0,39 |

| 7693 | 38 | 0,67 | 1,23 | 0,14 |

| 6560 | 50 | 0,65 | 3,09 | 0,27 |

| 7052 | 105 | 0,80 | 8,16 | 0,32 |